Roasting Machines for Production Batches of Any Size

The Tech-tisian RD-1 roaster from Roaster Dynamics LLC is a small batch drum roaster. It is capable of batch sizes from 100g to 1.25 pounds. Roaster times can be varied from 12-16 minutes. All contact points that the coffee will touch are made of stainless steel, the hopper, transition, drum, face plate, and cooler. The roaster utilizes a single blower with independent damper control for air flow to the drum and the cooler. The roaster is equipped with a DC motor to turn the drum. The DC motor has a potentiometer that is used to control the speed of the drum.

The roaster is equipped with two pressure gauges; one for incoming supply pressure, the second for pressure to the burner for burner control. All roasters are equipped with a Watlow controller, there are two versions used depending on the roaster configuration. The Manual version of the roaster has a single input, bean temp, while the Logging and Profiling versions have dual inputs; bean and environment temps.

All versions have a piezo spark ignite system built into the manual control gas valve. The manual control gas valve will allow you to light the pilot and manually control gas flow to the burner. The Profiling version has a second electronic modulating valve that the profiling system controls. If the bean temp reaches the set point temp on the Watlow controller, the burner will be turned off and require relighting, the Profiling version will turn the burner down to low fire once the set point temp is reached, and then back up if the temp falls below the set point temp.

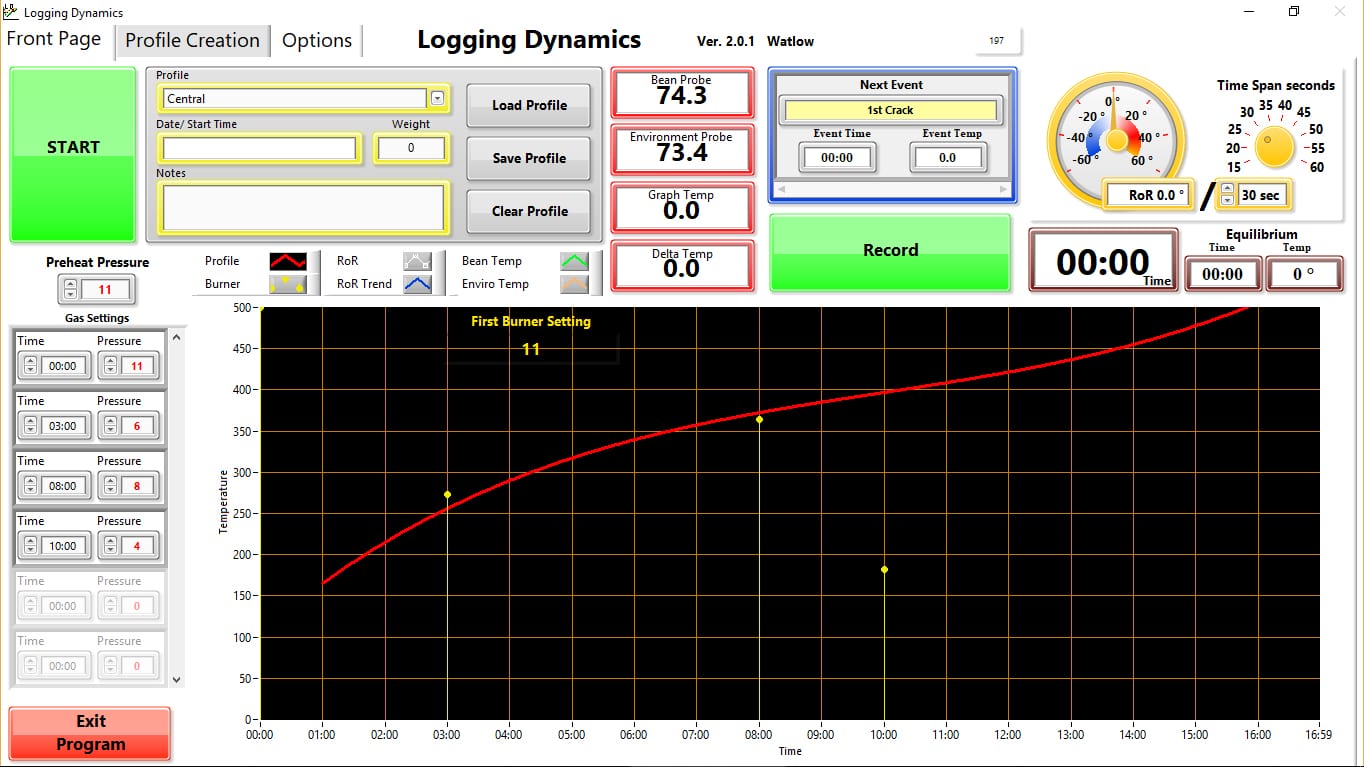

The Logging version comes with Logging Dynamics software, and communication cables.

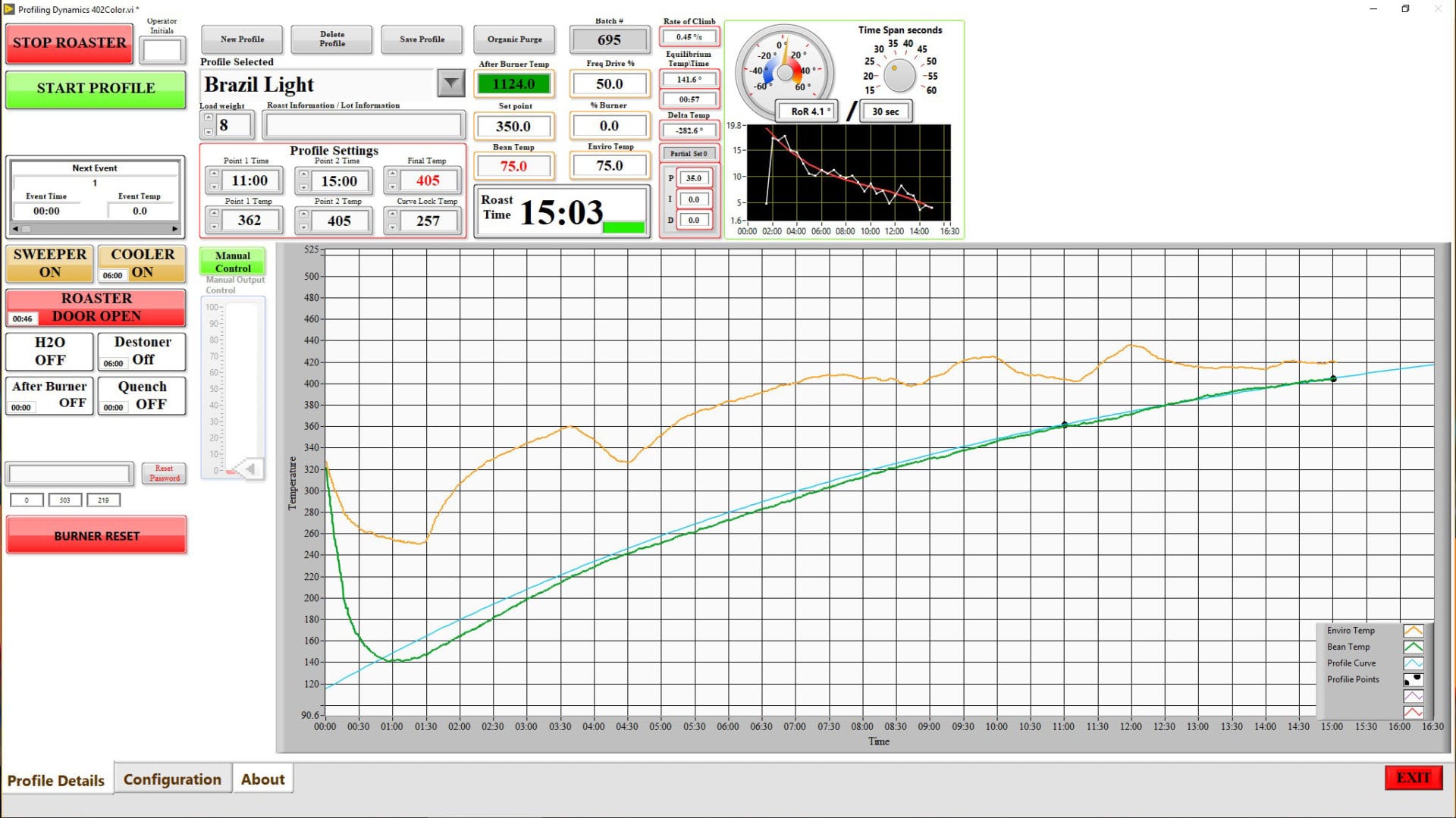

The Profiling version comes with Profiling Dynamics LITE system and communication cables.

Both the Logging and Profiling versions of the roaster will require the customer to supply a Windows 7, or 10 computer to utilize the included software.

The roaster will require a 40 inches wide x 42 inches long floor space, the roaster sits on an included stand putting the roaster at 38 inches from the floor.

The roaster weight is approximately 270 pounds

Requires a 4 inch exhaust duct to the outside

Can be setup with either propane or natural gas, 10,000 Btu’s

Gas versions will require 110V 60 Hz 6 amp power can be set up to work with 220 V AC power

The Tech-tisian RD-3 / RD-6 is an industry first in convertible roasters. The roaster can be configured and purchased as either a 3 kilo or 6 kilo max input roaster. The roaster can also be purchased as a 3 kilo roaster and at a later time upgraded to a 6 kilo roaster. The operator cabinet stands independently of the roaster and is connected through flexible conduit with quick release connectors. Roasting and cooling simultaneously allowing for 3-4 batches per hour.

The roaster utilizes stainless steel for all components that the coffee touches through out the roasting process; Hopper, transition from hopper to drum, drum face plate, drum, cooling bin, cooling paddles and discharge chute. There are view windows positioned so you can see the burner flame, roasting beans in the drum and in the transition to view green beans loading and to view into the upper portion of the drum while roasting.

Drum, Drum blower and Cooling stir all utilize DC motors. The Drum and Drum blower are equipped with variable speed digital potentiometers for adjusting the speed of each component. These motors will require that the brushes be changed every 2500 hours of operation for each motor, hour meters are provided to track each motors operation time. The cooling blower uses an AC motor.

The burner is controlled with a Watlow temperature controller. The controller has dual inputs, one for bean and one for Environment. The Environment probe is connected to an independent High Limit circuit built into the controller. A spark ignitor system is used to ignite the burner, allowing the burner to be off when not roasting. The gas train is equipped with a Maxitrol Modulating valve controlled by a potentiometer dial on the operator cabinet.

The operator cabinet can be positioned to work best for the operator. There is approximately 6 feet of flexible conduit between the roaster and the operator cabinet. The top of the cabinet is slightly angled to be used for a work surface or for positioning a computer. The operator cabinet has On/Off switches for: Power, Drum, Drum Blower, Stir, Cooler blower and Light. Emergency stop buttons for Power and Burner.Two digital potentiometers, 1 for Drum speed and 1 for Drum Blower speed. Three hour meters that track the time each DC motor has run, allowing the operator to know when it is time to change the brushes for that motor. An alarm is mounted in the face plate as well.

The roaster can be optionally equipped with either a data logging system (Logging Dynamics) or a Profiling system (Profiling Dynamics (LITE or With automation)). If either of these options are added, a data communication port will be added to the face of the operator panel for ease of connectivity.

The roaster has adjustable feet for leveling the roaster. There are removable panels between the front legs and both side legs, that utilize thumb screws for easy removal and replacement.

Specs:

- Hopper, Drum, Cooler Stainless steel construction

- Drum (40-65rpm) and Drum Blower (1100 -2000rpm) max 252 Max CFM Variable Speed DC

- Stir DC motor - Fixed Speed

- Cooling blower AC motor - 310 CFM

- Electronically adjustable gas valve. spark ignition

- Digital Bean and Environment temperature probes

- Independent High Limit control circuit

- Roaster Dimensions: 70L x 35 W x 78T inches

- Operator Cabinet Dimensions: 20L x 18 W x 46T inches

- Power: 110VAC 20 Amp dedicated circuit, or 220

- Gas: RD-3 45,000 Btu’s Max, Natural or Propane RD-6 67,000 Btu’s Max, Natural or Propane

- Exhaust: Two 4 inch exhaust ports. Can be run separately or combined into one single pipe

- Weight 650-700 pounds

The Tech-tisian RD-1/4 Bag is a commercial/industrial coffee roaster. The operator cabinet stands independently of the roaster and is connected through flexible conduit with quick release connectors. Roasting and cooling simultaneously allowing for 3-4 batches per hour.

The roaster utilizes stainless steel for; Hopper, transition from hopper to drum, drum, cooling bin, cooling paddles and discharge chute. The drum face plate is carbon steel with electroless Nickel plating, the cooling paddles are stainless steel with replaceable wear strips. There are view windows positioned so you can see the burner flame, roasting beans in the drum and in the transition to view green beans loading and to view into the upper portion of the drum while roasting.

The Drum and Drum blower are equipped with variable speed digital potentiometers for adjusting the speed of each component through Variable Frequency drives.

The burner is controlled with a Watlow temperature controller. The controller has dual inputs, one for bean and one for Environment. The Environment probe is connected to an Independent High Limit circuit built into the controller. A direct spark ignitor system is used to ignite the burner, allowing the burner to be off when not roasting. The gas train is equipped with dual redundant positive shut-off valves. The burner is a Low-Nox premix burner, flame adjustment is controlled by a variable speed combustion blower. Premix is achieved with a Venturi style mixer and a zero pressure regulator. Burner ignition is further safety protected through the use of two air proving switches, one on the drum blower ensuring exhaust is be pulled from the roaster on pushed to the outside, the second air proving switch ensures that the burner blower is pushing air through the Venturi before allowing the gas valves to open and ignition to spark.

The operator cabinet can be positioned to work best for the operator. There is approximately 6 feet of flexible conduit between the roaster and the operator cabinet. The top of the cabinet is slightly angled to be used for a work surface or for positioning a computer. The operator cabinet has On/Off switches for: Power, Drum, Drum Blower, Stir, Cooler blower and Light. Emergency stop buttons for Power and Burner.Two digital potentiometers, 1 for Drum speed and 1 for Drum Blower speed. An hour meter for maintenance intervals, and alarm and trier light switch.

The roaster can be optionally equipped with either a data logging system (Logging Dynamics) or a Profiling system (Profiling Dynamics (LITE or With automation)). If either of these options are added, data communication port, 3-way switches and control hardware are added for additional functionality.

The roaster has adjustable feet for leveling the roaster. There are removable panels between the front legs and both side legs, that utilize thumb screws for easy removal and replacement.

Specs:

- Hopper, Drum, Cooler Stainless steel construction; face plate carbon steel powder coated outside only

- Drum (45-60rpm) and Drum Blower (800 -3450rpm) max 252 Max CFM Variable Speed

- Stir - Fixed Speed

- Cooling blower AC motor - 800 CFM - Fixed speed

- Electronically adjustable burner flame, direct spark ignition

- Digital Bean and Environment temperature probes

- Independent High Limit control circuit built in to the Watlow controller

- Roaster Dimensions: 70L x 35 W x 78T inches

- Operator Cabinet Dimensions: 20L x 18 W x 46T inches

- Chaff Collector 28 diameter 86T inches

- Power: 208-230VAC 1ph 40 Amp dedicated circuit

- Gas: 150,000 Btu’s Max, Natural or Propane

- Exhaust: One 4 inch roaster and one 6 inch cooler exhaust ports. Recommended Jeremias Stainless steel Double wall Insulated pipe or equivalent.

- Weight: Combined weight Approximately 1400 pounds